Paper provides a tangible connection. It helps you learn and retain information better. It’s also secure and provides an accessible option.

The first paper mill built in the U.S. was in Pennsylvania in 1690

Paper notetakers complete tasks 25% faster than digital notetakers

The paper industry recycles nearly 60% more paper today than it did in 1990

Examples of Paper

Within the industry, paper is also referred to as printing and writing papers.

Printing and writing papers are used to make:

- Copy and printer paper

- Books

- Magazines and catalogs

- Newspapers

- Sticky notes

- Braille paper

- Folders

- Manuals

- Index cards

- Cardstock

- Construction paper

- Greeting cards

- Envelopes

- Notebooks and journals

- Receipts

- Maps

- Posters

- Book jackets

Member Spotlight

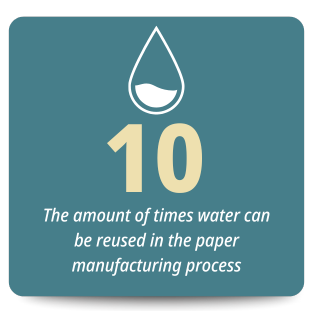

"We want to utilize all of the water that we bring in. We want to utilize it as much as possible. We do that because water is a precious resource. Having it come through once and then discharging it is not a good stewardship of that resource.

We work really hard at trying to reduce that water. We talk about it on a daily basis at Cloquet."

Dan Menor, Environmental Engineer, Sappi

What is Paper Made From?

Our industry responsibly manufactures printing and writing papers using:

- Trees from sustainably managed working forests where trees are replanted

- Recycled paper

Printing and writing papers come in different grades or types. Making different grades of paper is a lot like following a recipe. Paper manufacturers need to balance using fresh wood pulp and recycled paper.

Did You Know

Learn more about forest managementThe U.S. pulp and paper industry is not linked to global deforestation. On managed forests, trees are replanted to continue the cycle of growing.

What are the Benefits of a Paper Choice?

Paper continues to offer many advantages in an increasingly digital world. Balancing digital and paper-based options is beneficial.

Accessible: Paper ensures everyone has access to crucial documents. Digital divides still exist, and according to the Federal Communications Commission, 25% of rural Americans do not have broadband access. Braille paper provides an opportunity to learn through touch.

Secure: Many digital files are susceptible to accidental deletion, data corruption, or technology failures.

Permanence: Important documents like marriage and birth certificates, adoption papers, diplomas and social security cards are frequently printed on paper.

Information Retention: Studies show reading on paper helps readers better comprehend information. So does taking notes on paper.

Member Spotlight

See how the partnership will improve forestsSylvamo recently announced a 5-year partnership with the National Fish and Wildlife Foundation (NFWF) to support forests throughout the Northeast U.S. They will donate approximately $250,000 annually to support multiple grants that help enhance forest resilience.